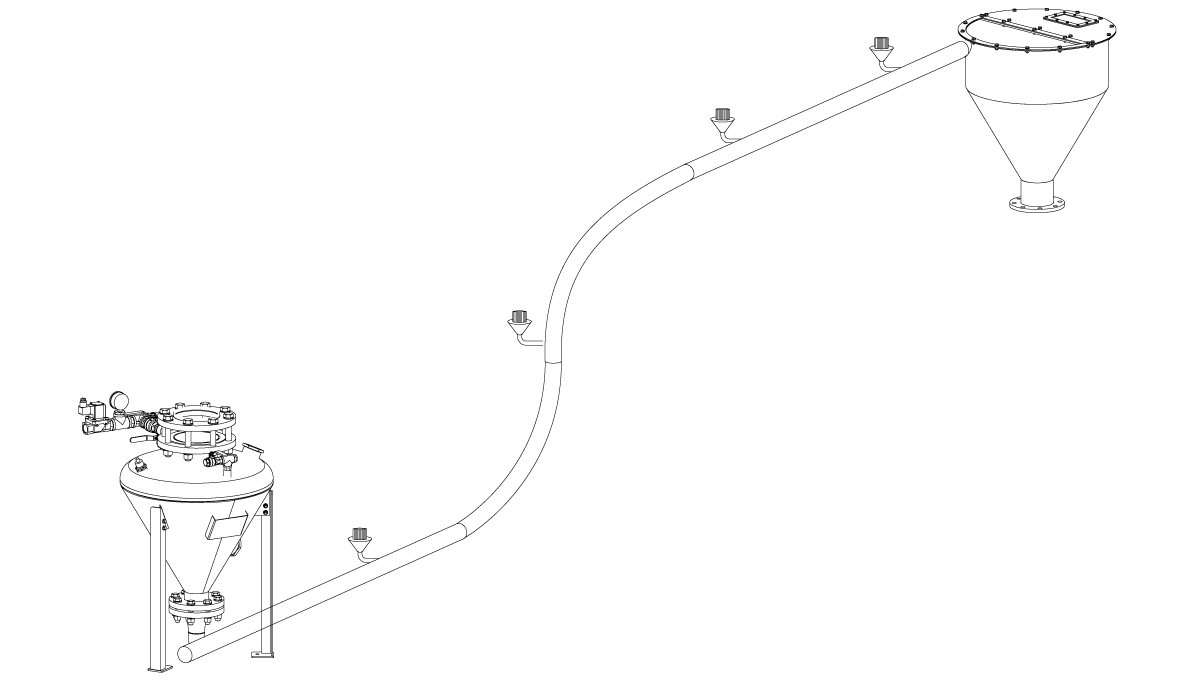

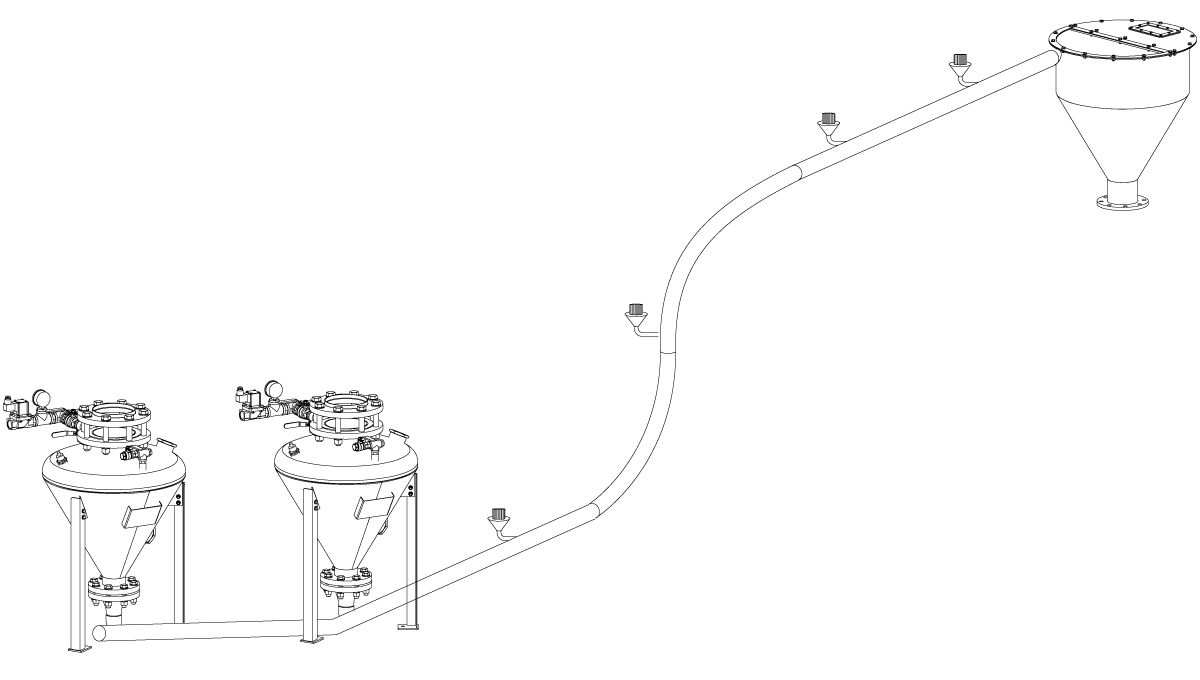

Dense phase

pneumatic conveying

of solid products

Company

We are an engineering company with a large experience in industrial installations for the reception, storage, transport as well as the ingredient dosing into manufacturing processes. Moreover, we are specialists in developing technology, producing machinery and creating installations for a wide range of sectors such as the feed and food, cosmetic, chemical, and pulp and paper industries.

Over the last 30 years we have been developing a great number of successful installations and controls to help our customers in their needs of dosing great quantity of ingredients.

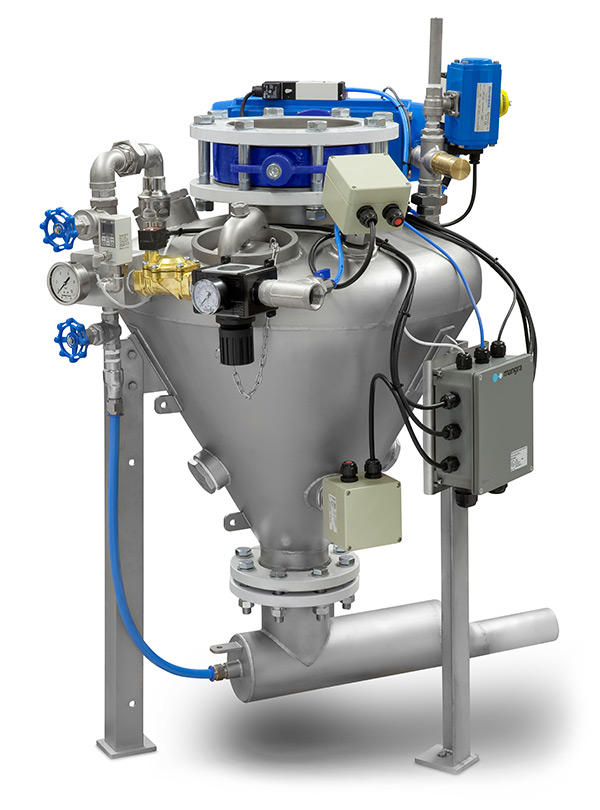

At MANGRA we design, manufacture and set up storage and reception tanks, chemical preparation equipment, ingredient dosing equipment, filtration systems, process control systems, heat exchangers (steam and electrical) and the complete piping and all the components needed to perform a turnkey installation.

Thanks to our highly qualified team which is permanently innovating and doing research we own a leadership position in the ingredient dosing and control market.

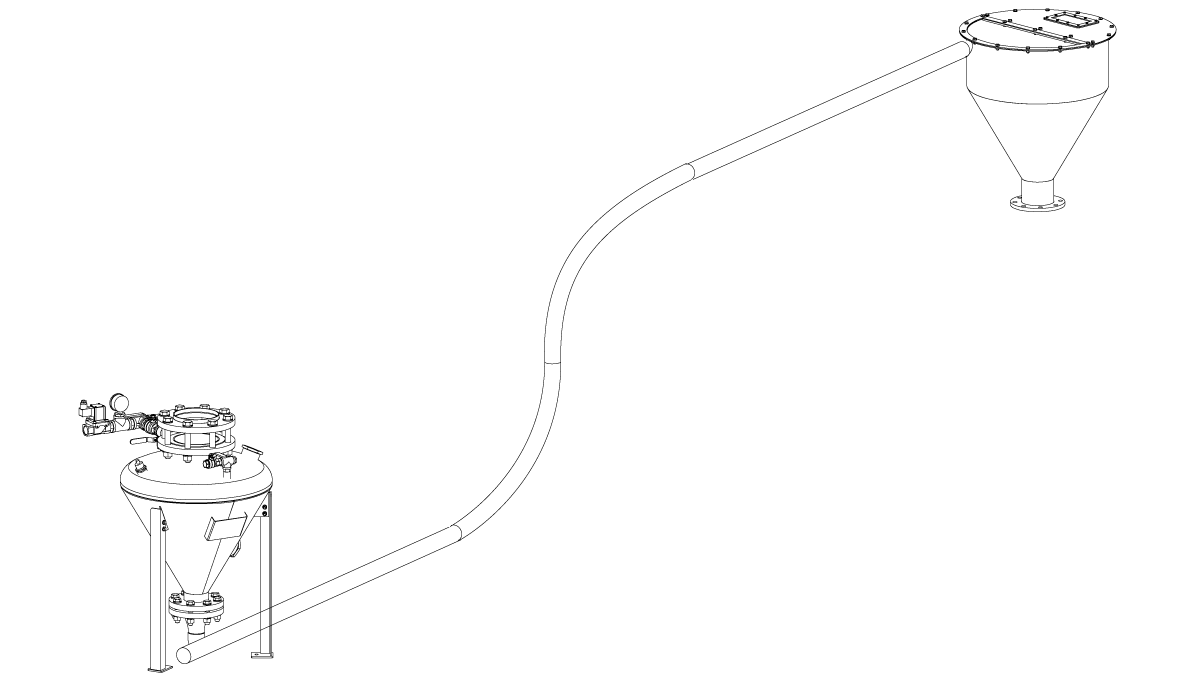

What is more, because of our state of the art dense phase pneumatic transport technology, which transports either granular or powder material,we are proud to claim that our customers are provided with the most competitive advantages for their businesses.

Not only this innovative technology allows energy cost savings, but it also has a flexible application and no maintenance at all and it replaces conveying belts, bucket elevators, screw conveyors and dilute phase pneumatic transport.

Finally, our system optimizes significantly the conveyance process and minimizes the installation and start up costs.

Our customers will be assisted by specialized engineers in the design of the installation, technical support and mechanical assembling. Furthermore under customer request we can supply with turnkey basis.

Equipment available in AISI 304 or AISI 316 stainless steel, for temperatures up to 200°C and ATEX 21 and ATEX 22 configurations.

Our technical office is at your disposal to develop any needed customized request to help you grow your business.

Advantages

Closed system which avoids dust emissions and contamination.

Conveyance of the product beyond 500 m. Capacity up to 200 tph.

Smooth transport system, specially designed for fragile product.

Low maintenance and durability of the material.

Low consumption of air and energy.

Flexible conveyance pipeline which optimizes the space needs.

Great efficiency and performance.

Small conveyance pipe diameter. Ability to convey abrasive products using slow speed.

Ability to convey abrasive products using slow speed.

Practical, easy to install and expand.

Lighter and heavier particles are not separated apart during the transport process.

Small air filter at destination.

Fast return of investment.

Comparative

Dense phase vs dilute phase pneumatic conveying

| Dilute phase pneumatic conveying with blower | vs. | Dense phase pneumatic conveying with pressure vessel | |

|---|---|---|---|

| Flow | 19T/h | 19T/h | |

| Distance | 150m | 150m | |

| Pipe diameter | Ø204 | -40% |

Ø115 |

| Air flow | 4.000m3/h | -90% |

400m3/h |

| Conveying pressure | 0,8bar | 3,1bar | |

| Power consumption blower/compressor | 99kw | -63% |

35kw |

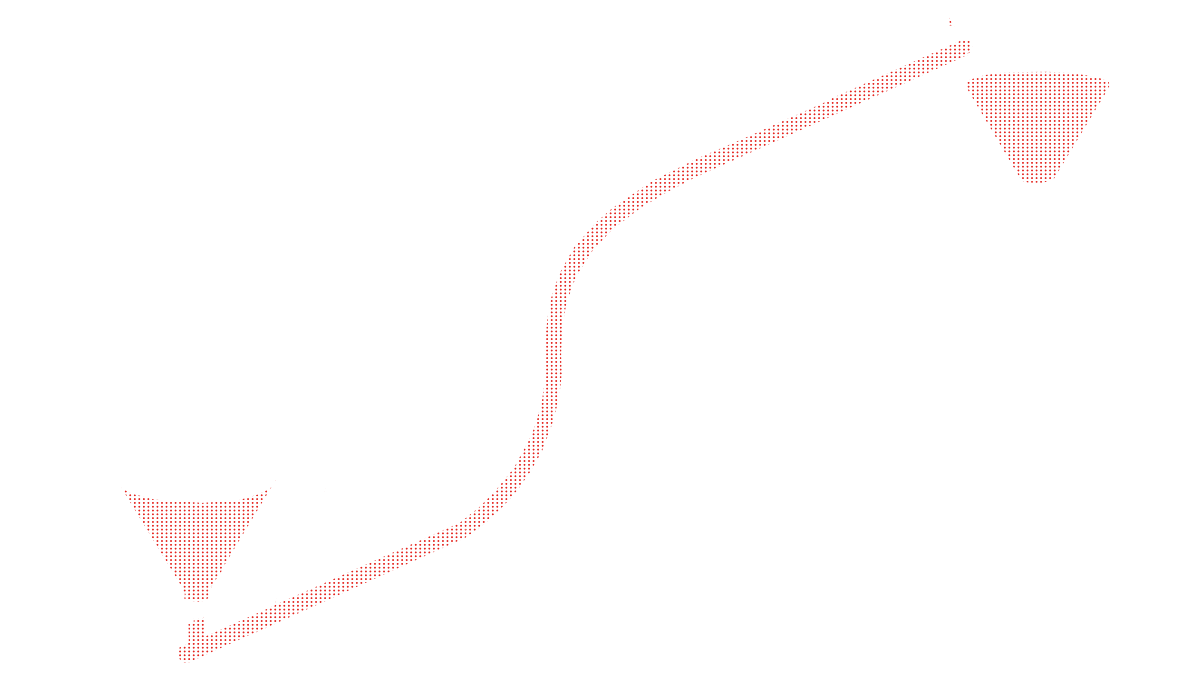

Dense phase pneumatic

conveying modes

Empty Line conveying mode

Class versatility & Efficiency

Pipe is emptied after each cycle.

Full Pipe conveying mode

Class High Performance

Pipe is emptied only by the operator order.

Doble Full Pipe conveying mode

Class Doble High Performance

Used for large distances and big flows

Some conveyed

products

- Acrylamide

- Acrylic modifier

- Active carbon

- Adipic acid

- Alumina

- Alumina cement

- Aluminium fluoride

- Aluminium nitride

- Aluminium silicate

- Anhydrous borax

- Ascorbic acid

- Atomized aluminium powder

- Barium and strontium sulfate

- Barium sulfate

- Barley malt

- Base granules detergent

- Bed ash

- Bentonite

- Bicarbonate

- Biscuit mix

- Black cement

- Black sand

- Blended glass batch

- Bone meals

- Borax

- Boric acid

- Bran flakes

- Bread crumbs

- Brown sugar

- Burnt sand

- Cake mix

- Calcined alumina

- Calcium aluminate

- Calcium carbide

- Calcium carbonate

- Calcium fluoride

- Calcium oxide

- Calcium phosphate

- Calcium silicate

- Calcium stearate

- Calcium sulfate

- Carbon black

- Carbon black granules

- Carbon black pellet

- Carbon Mix

- Carnalite

- Cat Food

- Catalyst

- Celite

- Cellulose

- Cement

- Cement blend

- Ceramic

- Ceramic dust

- Cereals

- Chamomile

- Charred wood

- Chewing gum base

- Chicken seasoning

- China clay

- Chopped fiberglass

- Chromic acid

- Citric acid

- Clay

- Clay calcined

- Clay tile

- Coal

- Coal dust

- Coal slag

- Coarse salt

- Cobalt oxide

- Cocoa

- Coffee grounds

- Coke

- Coke Calcined

- Copper Powder

- Corn

- Corn Gluten Meal

- Corn Grits

- Couscous

- Crispy rice

- Crushed glass

- Crushed rock

- Cryolite dust

- Desiccated coconut

- Dextrose

- Diatomaceous earth

- Disodium phosphate

- Dog Food

- Dolomite

- Dried Anthracite

- Dried peas

- Dried sludge

- Dried sludge Pellets

- Dry ash

- Dry soap

- Epoxy resin

- Ethylene vinyl acetate

- Felspar

- Ferrite

- Fiberglass

- Fine boric acid

- Fine dry ceramic

- Fine salt

- Fish food

- Fly ash

- Foundry dust

- Freeze dried coffee

- Frit

- Fructose

- Fruit granulated sugar

- Fumed silica

- Glass batch

- Glass beads

- Glass cullet

- Glass frit

- Granola

- Granulated sugar

- Graphite

- Green coffee beans

- Green oats

- Groats

- Ground gypsum

- Gypsum

- Hydrated alumina

- Hydrated lime

- Hydroquinone

- Ilmenite

- Iron oxide

- Iron oxide brown

- Iron oxide red

- Iron powder

- Lactose

- Lignite

- Lime

- Limestone

- Long grain rice

- Magnesite

- Magnesium chloride

- Magnesium oxide

- Maltodextrin

- Manganese dioxide

- Marble chips

- Medicinal herbs

- Medium grain rice

- Melamine powder

- Metal powder

- Metallurgical coke

- Mica

- Mica Ground

- Micronized coal

- Milk powder

- Milled zircon

- Mineral black

- Mixed sand and soda ash

- Molybdenum oxide

- Monoammonium phosphate

- Mortar mix

- Mush

- Nickel carbonate

- Nickel granules

- Nickel oxide

- Nickel sulfate

- Nylon pellets

- Oat flakes

- Olivine sand

- Paper pulp

- Parmesan cheese

- Peanuts

- Pellet silicon dioxide

- Pelletized paper pulp

- Perlite

- Petroleum coke

- Pharmaceutical gelatin

- Phenolic resin

- Phosphoric anhydride

- Pink Beans

- Plastic caps

- Plastic Pellet

- Plastic resin pellets

- Polyester

- Polyester pellets

- Polyethylene

- Polyethylene glycol

- Polyethylene pellets

- Polyethylene powder

- Polymerized urea

- Polypropylene

- Polypropylene pellets

- Polystyrene

- Polystyrene pellets

- Polyvinyl chloride

- Popcorns

- Portland cement

- Potash

- Potassium carbonate

- Potassium sulfate

- Potato flakes

- Potato flour

- Potato starch

- Prilled ferrous sulfate

- Pvc coumpound

- Pvc powder

- Pvc resin

- Pyrite concentrate

- Reclaimed sand

- Red lead

- Refractory batch

- Resin

- Resin copolymer

- Resin powder

- Resin-coated sands

- Rice

- Rice Grains

- Rock dust

- Rye flour

- Saccharin sodium

- Salt crystals

- Sand

- Scrap glass

- Silica

- Silica flour

- Silica sand

- Silicates

- Silicon carbide

- Silicon dioxide

- Silicon powder

- Snuff tobacco

- Soda ash

- Sodium bicarbonate

- Sodium carbonate peroxide

- Sodium chlorate

- Sodium citrate

- Sodium fluoride

- Sodium nitrate

- Sodium perborate

- Sodium percarbonate

- Sodium polyacrylate

- Sodium stearate

- Sodium sulfate

- Sodium triphosphate

- Soy protein powder

- Soybean meal

- Spodumene

- Starch

- Sugar

- Sugar mint

- Superabsorbent polymer

- Talc

- Tannin free tea

- Tea

- Tile dust

- Titanium dioxide

- Titanium slag

- Toasted coffee beens

- Tobacco

- Trisodium phosphate powder

- Urea prills

- Vermiculite

- Vinyl resin

- Vinyl tile chips

- Wet clay

- Wheat flour

- Whole corn

- Wollastonite

- Yellow cement

- Zeolite

- Zinc oxyde

- Zinc powder

- Zinc stearate

- Zirconium

- Zirconium carbonate